An effective solution when wishing to activate or clean the surface of a material, Atmospheric Plasma Surface Treatments are ideal for inline processing. They’re also an excellent choice to plasma treat targeted areas of larger components, particularly those that would be too big for Vacuum Plasma Treatment. It’s a great way of increasing the adhesive properties of a surface, making it much easier to bond, paint or glue.

The simplicity of Atmospheric Plasma Surface Treatments make our systems a popular choice amongst customers, especially with them being cost-effective and easy to install. As a result, Tantec UK & Ireland are proud to offer an innovative portfolio of systems ready to meet our clients needs.

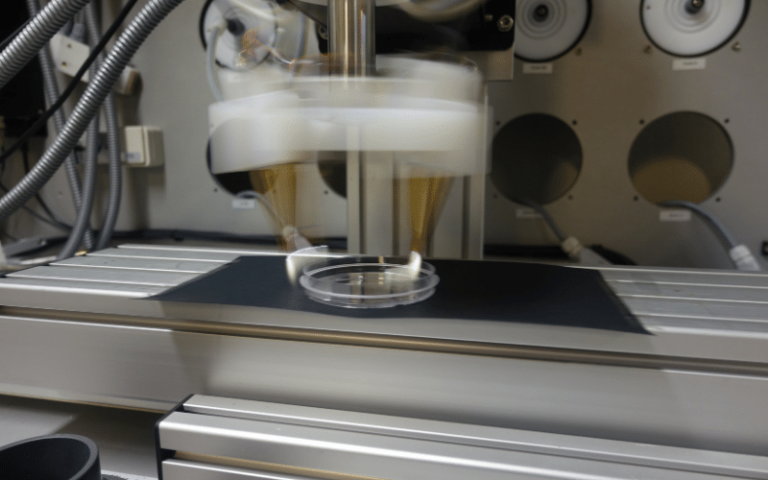

Ideal for incorporation into automated industrial processes, atmospheric plasma nozzles can either be attached to a fixed point or a multi-axis robot. Plasma is created by swirling a vortex of compressed air around a high voltage discharge; this is then blown out of the nozzle and directed to the part. Due to the nature of the treatment’s application, the substrate experiences either none or a minor amount of heating. This means it is ideal for the treatment of materials such as polymers, glass, ceramics and metals.

Tantec UK & Ireland’s flagship plasma system, the PlasmaTEC-X (PLX), is able to run as a single system or can be expanded to include up to eight nozzles from a single controller. Users are able to enjoy a range of features including boost mode, air save and pulse mode. Thanks to its robust, lightweight and compact size, it is ideal for mounting onto a robot providing accurate and controlled plasma treatment over the surface. This works particularly well when paired with adhesive dispensing. Alternatively, it is also able to be placed above an extrusion line for cables, pipes and other plastic products to aid with print adhesion, over moulding or other processes following extrusion.

Our versatile PlasmaTEC-X OEM is a single nozzle, without the need for operator intervention and entirely controllable by a remote PLC. These systems work perfectly with robot cells and other automated production with built in control for the entire process. Various inputs and outputs are available for starting the unit, reading ready or any alarms. These systems keep cost and complexity to a minimum, while offering the same performance and reliability of the PlasmaTEC-X system

Tantec UK & Ireland’s SpinTEC machines utilise the same systems as the PlasmaTEC-X Multi, however, it has a dual plasma head that rotates at high speeds of up to 1000 rpm, whilst providing treatment widths of between 40mm and 150mm. Of course, these treatment widths are able to be customised in order to fit our client’s treatment requirements.

Our SpinTEC systems are often used when looking for extra width for 3D components or when Corona Treatment Systems are not appropriate.

Tantec have worked closely with automation and collaborative robot manufacturer Universal Robots to become a certified UR+ partner. The PlasmaTEC-X UR interfaces with the robot with a simple plug and play set up, coming with the required brackets and supports to install the Plasma head to the robot.

Collaborative robots make for easy installations with simple to program and use software and hardware. As with the PlasmaTEC-X and OEM versions, the highly efficient plasma treatment can run at high speeds, perfectly controlled by a Universal Robot.

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com