Corona Surface Treatments are designed to increase surface energy across a wide variety of metals and plastics. By adding these adhesive properties to a material, a range of printing or bonding processes can then take place. Some Corona Surface Treatment Systems are built to standard specifications, such as fixed width web treatment systems, but, if required, custom equipment can be tailored for your needs. This often applies to those industries working with flat, wide materials or with high-speed requirements. Tantec UK & Ireland are proud to offer our customers an innovative range of standard and bespoke corona systems, ensuring your needs are met – no matter the complexity of your product.

For nearly 50 years, we have been at the forefront of this exciting technology. While we didn’t invent it, we have certainly pioneered its continued development and its importance can not be understated. From its origins in 1951, it launched an entire industry and has gone on to change the world of manufacturing. Our Corona Systems provide rapid-speed treatments that enable in-line high performance. It’s testament to the quality of this process that it has stood the test of time, often outperforming new, emerging technologies.

Tantec UK & Ireland have been supplying Corona Surface Treatment Systems to customers across a wide-range of industries including the plastic film, extrusion, automotive and medical sectors.

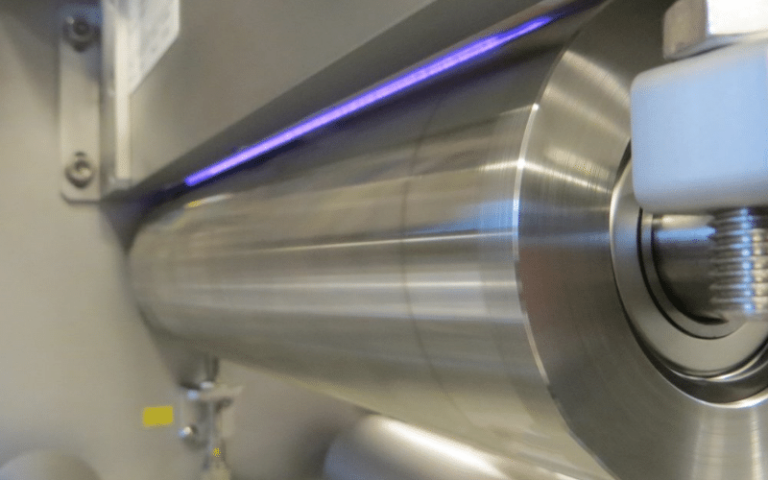

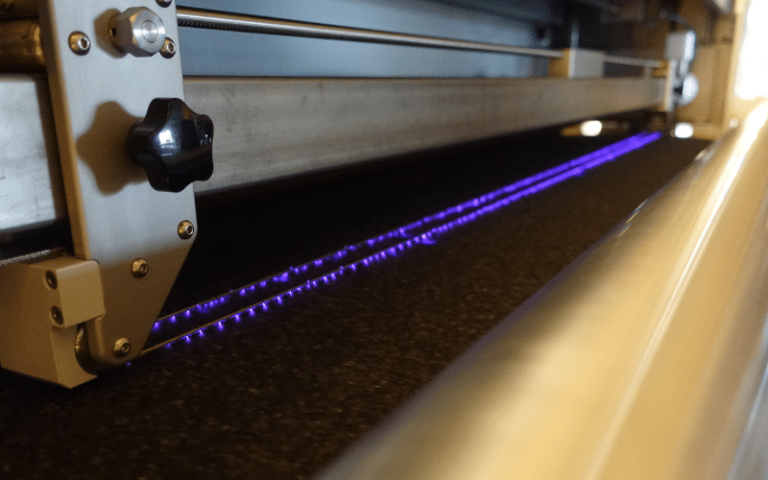

Corona Surface Treatments prime materials with a high frequency discharge. This changes the properties of the material to become more receptive to adhesives, inks and coatings. It’s purpose is to optimise the adhesive properties of polymer-based materials. This is because polymer-based substrates often have a low surface energy, leading to the poor adhesion of inks, glues and coatings, which typically have high surface tensions. It therefore works by breaking oxygen molecules into atomic form. They then combine with molecule ends present in the material being treated, changing the characteristics of its surface, turning it chemically active. Optimum adhesion is then achieved when the surface energy of the substrate is equal or higher than the surface tension of the liquid being applied to the substrate.

As with Plasma, Corona can have a treatment life. A wide range of treatment life can occur and is dependent on three key factors – contamination such as finger prints or airborne oils, additive migration such as plasticisers and other additives blooming to the surface, and molecular movement in softer, none crosslinked materials. We can test for treatment life in our labs for customers needing longer processing windows, but for most materials the window is at least days and is often months or years.

Tantec are one of the world’s leading manufacturers of Corona Surface Treatment Systems which have been designed and manufactured since day one of the company, back in 1974. Corona Discharge treatment, is often the more engineered and bespoke systems so can come in hundreds of designs depending on the material, the geometry of the part, process speed, treatment intensity and integration/ installation requirements.

If Corona Treatment, sometimes known as dielectric barrier discharge treatment looks like the treatment system for you, make sure you speak with us as there’s always more to the technology than first meets the eye.

A few of the key systems we manufacture include:

Designed for the pretreatment of conductive or nonconductive narrow webs, our LabelTEC Corona Surface Treatment Systems can accommodate a variety of materials with widths of between 50mm-500mm. They treat either one or both sides of the web and run at production speeds up to 250m/min. LabelTEC systems are ideal for priming materials ahead of laminating or printing processes. Wider systems are available, but move from simple bolt on, cantilevered systems to larger installations.

Larger Corona systems include the FoamTEC and SheetTEC systems, which can treat foams and sheets which can be thick or delicate and have large widths. Foams for example, with their varying surface finish can be damaged easily if not treated right. Equally, fixed sized boards require specific handling to ensure they’re treated correctly from edge to edge, front to back.

These systems can be installed into more complex production environments, such as coating lines, or they can be stand alone systems manually loaded and unloaded.

Treatment of 3D components such as syringes, lenses or bottles generally uses versions of the RotoTEC or SyrinTEC systems, which are designed to work with a conveyor line, or a jig and rail inline set up. This way, a part or bank of parts can come along a line and pass through the treatment area as the parts move on to their next stage with speed matching the rest of the process.

These processes can also be offline, treating parts manually loaded, or presented via a rotary table or bowl feeder. RotoTEC and SyrinTEC are often used for coating adhesion, label application or print adhesion, especially for safety critical print.

Our low frequency system, SpotTEC, is a cost effective solution, ideal for parts, usually running up to 30m/min. The SpotTEC nozzle based system can run up to 65mm wide per head and requires little engineering to install in to most production lines.

Our innovative SpotTEC systems blow a high-voltage discharge towards the substrate surface in a similar way to Atmospheric Plasma. Commonly used for the treatment of cables, profiles and injection moulded parts, they are easily integrated into extrusion lines or in to automated systems such as robot applied treatment. They’re an excellent pre-treatment option with low investment and running costs.

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com