How to use Dyne Pens and Test Inks

Read this to find out the official way to get

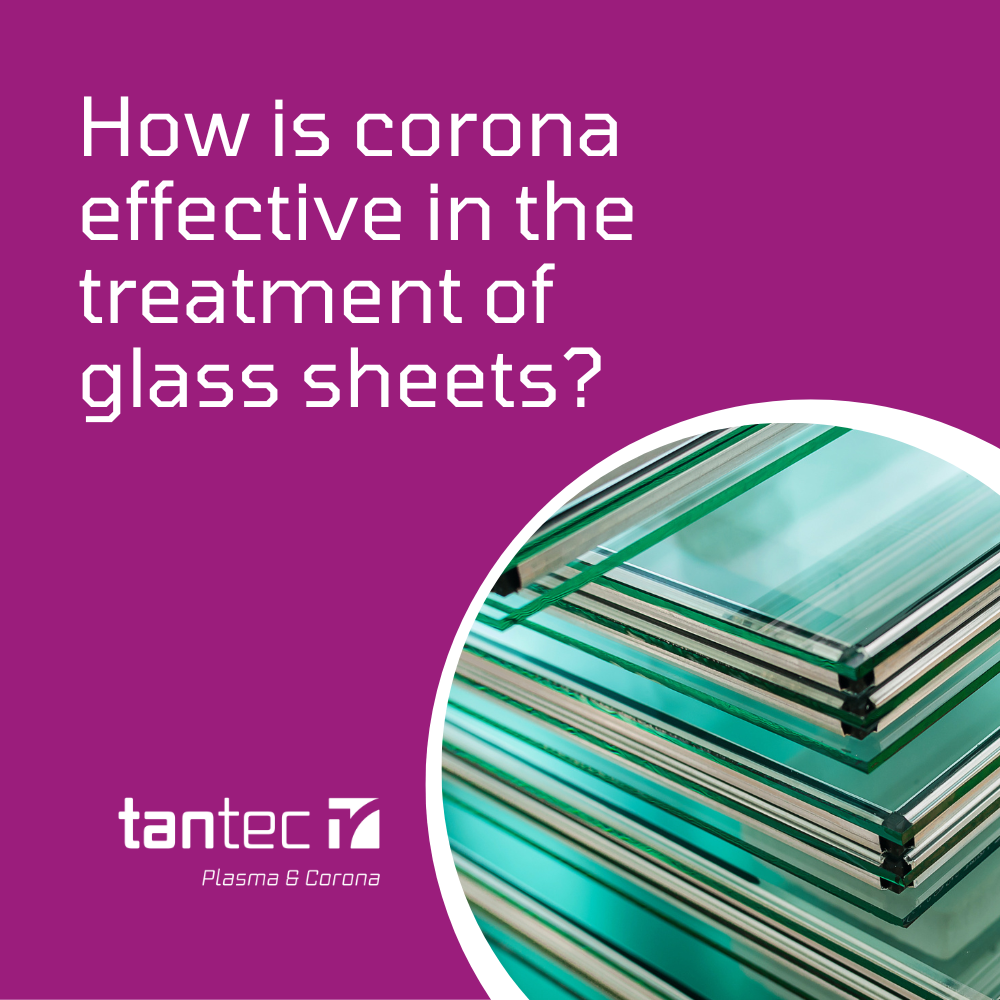

It is often necessary to coat glass sheets as part of the manufacturing process. For liquid adhesives, glues, coatings or inks to adhere to the surface of molded or extruded plastics, increasing surface energy will improve surface wettability, thereby promoting stronger adhesion. In our latest blog, we take a look at how corona is effective in the treatment of glass sheets.

The purpose of surface treatment of polymer based materials is to increase surface wettability through electrical discharge. The low surface energy of polymer based substrates often leads to poor adhesion of inks, glues and coatings. To obtain optimum adhesion, it is necessary to increase the surface energy of the substrate to just above that of the material to be applied. Corona treatment results in improved surface adhesion properties. In order for liquid adhesives, glues, coatings or inks to adhere to the surface of cast, moulded or extruded plastics we must first modify the surface. The process of increasing surface energy will improve surface wettability, thereby promoting stronger adhesion. This is perfect for glass sheets.

Corona treatment of sheets is also considered an environmentally friendly process which runs at fairly low power consumption. Although ozone is generated as a bi-product of the corona discharge, it is easily eliminated either through existing exhaust systems or through a custom-built Tantec ozone neutralising system. Materials such as PP, PE, PVC. PVDA, PMMA, PS and other non-conductive polymers are treated successfully with this concept.

What is SheetTEC?

SheetTEC can be installed as a stand-alone unit or with a conveyor system for integration into existing production lines. It is available as a single or double-sided surface treatment system and is equipped with metal electrodes for the optimised treatment of non conductive polymer materials.

Thanks to the high voltage technology developed by Tantec it is possible to treat sheets over the edges and even sheets where the edges are slightly bent. The processing speed of the sheets may vary between 0.5 m and 10 Mtr. / Min. SheetTEC ensures uniform treatment of boards up to 50 mm in thickness.

How can SheetTEC help with the treatment of glass sheets?

Tantec has just delivered a complete SheetTEC solution for a customer in Europe, where there is a demand for high-quality surface treatment of glass plates. The processed plates are clean and prepared for glueing and coating with Corona treatment.

Treatment of glass plates for this application may vary from 50 mm to 1000 mm, which gives the customer treatment flexibility for small and large plates. SheetTEC is equipped with a metal electrode, which does not affect glass profiles. The result is that the items are not damaged during treatment.

Tantec UK & Ireland are one of the world’s leading providers of Plasma and Corona Treatment Systems. Our specialist surface treatment systems are trusted by major manufacturers across the globe. With over 40 years of expertise in the manufacturing and supply of high-specification surface treatment systems for metals and plastics, our experts also offer a comprehensive range of sub-contract manufacturing and testing services. Either way, we can ensure your product’s adhesive properties are elevated to the highest industry standards. To discover more on Corona surface treatment by visiting our website here.

Read this to find out the official way to get

Polypropylene (PP) bonding is traditionally a difficult task due to

Composites are becoming increasingly important in manufacturing, whether these are

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com