How to use Dyne Pens and Test Inks

Read this to find out the official way to get

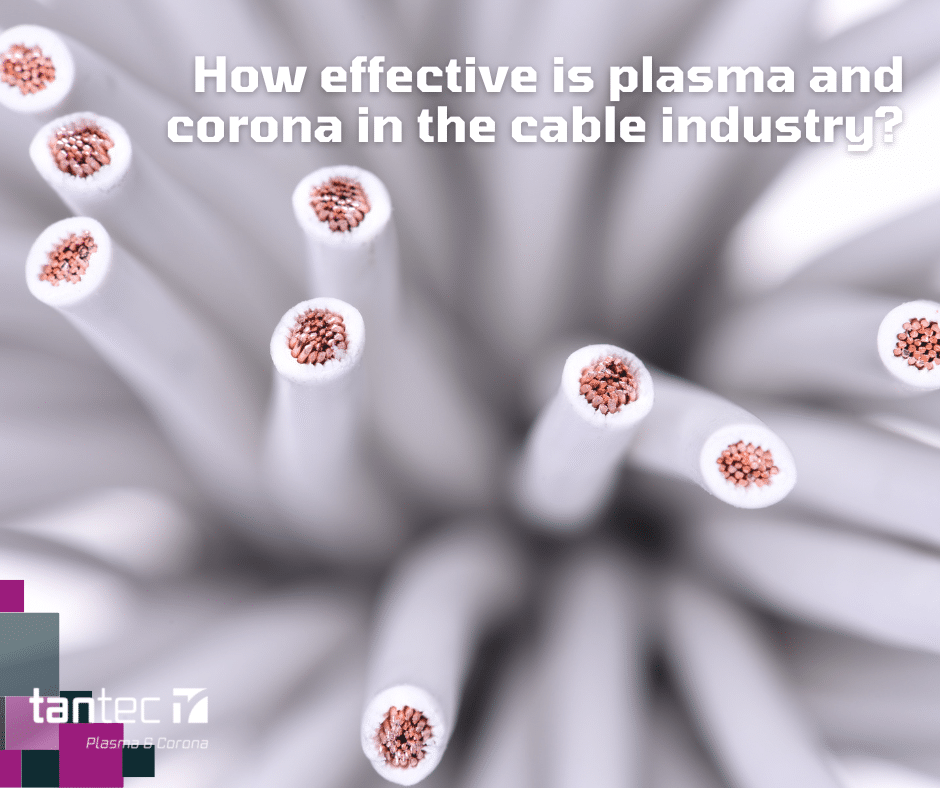

Is plasma and corona effective in the cable industry? Whether cabling around your car, oven, home or office, large high-tension cables powering towns and cities, or data cables carrying digital signals around the world; people and machines around the globe are supplied with power and information by billions of cables. They form a worldwide infrastructure and are the lifelines of a digitised world, with enormous data streams flowing through them. This makes quality and innovation all the more important in modern connection technology – an industry which is attaching increasing importance to high-quality corona and plasma treatment processes.

If cables (and pipes too) have poor quality print, or not at all, this can result in major financial losses or errors in installation. Tantec offers corona and plasma pretreatments which are unmatched in their reliability. An example of how effective plasma cleaning in the cable industry was Tantec’s work with Helukabel.

Helukabel, an internationally successful family business with 1,700 employees and an annual turnover of 600 million euros, stands for the highest level of production standards. The hidden champion is situated in Hemmingen near Stuttgart with 58 productions and sales locations in 37 countries are one of the world’s leading suppliers of cables, pipes, and component parts.

Helukabel’s portfolio comprises a big selection of standard products and customised solutions for numerous industries. ”Reliability is our most important currency”, says Ömer Durak, Head of Cable Construction, summarising the company’s secret of success. One of Helukabel’s areas of expertise: Cables for 50 cm large cable-robots equipped with cameras, measuring equipment and nozzles – a high-tech device for municipal sewage systems.

Technologically, these cables are considered the ”supreme discipline”, the graduate engineer explains – because from controls to cleaning liquid to compressed air, everything is in one cable. The second challenge: An isolation of a special elastomer with poor printability.

The labelling of pipes with numbers or letters is a potential source of errors and hence considered very risky, Durak explains: ”If pipes are printed with poor quality, or not at all, this can result in major financial losses.” To avoid such worst-case scenarios during production, Tantec offers corona pretreatments which are unrivalled in their reliability.

Tantec’s modular CableTEC system guarantees us a flawless, effective and safe production chain. Because of the low surface energy of most insulation covers, ink and coatings usually do not adhere to them, which makes a corona surface treatment indispensable in the cable Industry. As a part of this treatment, organic residues and contaminants are removed by a high-voltage discharge and the surface energy is increased, so that ink and plastic can bond.

Plasma cleaning in the cable industry: Tantec scores with high speed and reliability. Our world-class surface treatment systems utilise Plasma or Corona Treatments to ensure the component’s surface provides the optimum conditions required for your chosen adhesive. We work with some of the world’s leading OEM, tier one and tier two suppliers in industries including automotive, aerospace and medical devices.

Tantec UK & Ireland are one of the world’s leading providers of Plasma and Corona Treatment Systems. Major manufacturers trust our specialist surface treatment systems across the globe. With over 40 years of expertise in the manufacturing and supply of high-specification surface treatment systems for metals and plastics, our experts also offer a comprehensive range of sub-contract manufacturing and testing services. Either way, we can ensure your product’s adhesive properties are elevated to the highest industry standards.

For further information on surface treatment please visit www.tantec-uk.com

Read this to find out the official way to get

Polypropylene (PP) bonding is traditionally a difficult task due to

Composites are becoming increasingly important in manufacturing, whether these are

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com