You may see inks used to measure the energy of a surface referred to by various names including test inks, dyne pens, surface energy inks and jumbo test pens. All utilise the technique of placing a known and controlled test fluid onto an unknown surface. It helps us to determine the surface free energy – also known as the dyne level. This is a great indicator of how your material will perform; for example, if you need 40 dynes for your process, and your normal 40 test ink results in a failure, you’ll know the print quality will be poor. All of the inks we make are compliant according to ISO8296, ASTM D2578 and TAPPI T698 standards.

Many of our customers here at Tantec UK & Ireland purchase our world-class portfolio of test inks to examine the characteristics of both plastic and metal components – as well as their surface cleanliness. As the surface energy of the majority of contaminants is considerably lower than metals, the higher the dyne level of the part, the cleaner it is. We’re able to treat a wealth of products including incoming materials, treated components and cleaned and machined metals.

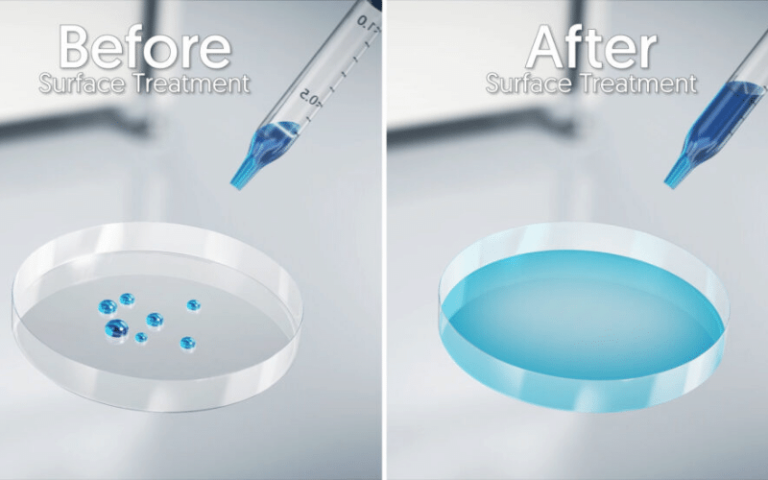

If you’d like to use our corona test inks, all you need to do is apply the test fluid to the surface of the material. The liquid will either spread to form a consistent film across the surface or retreat into droplets. If our test inks remain as a film for more than three seconds, then the material will have a minimum surface energy in mN/m of that fluid value. However, if the test ink retreats into droplets in under a second, then the surface energy of the substrate is lower than that of the liquid value. We’re able to specify the precise surface energy by applying a range of increasing or decreasing values of test inks.

Our world-class tensile testing systems are an effective way of conducting comprehensive adhesive testing, allowing us to quantitatively put a value on the performance you’ll receive from the finished product. They work well alongside test inks, ensuring you can be confident that your product’s material will perform to specific levels required. Furthermore, it also allows us to reap real-world data in a controlled and repeatable manner; something that is critical when our customers are considering the purchase of one of our surface treatment systems. Thanks to repeated testing, our experts can determine the adhesive with the best strength, repeatability and quality that will work best for you.

While adhesive bonding tends to be the most common use for our tensile testing systems, by using lap shear coupons we can also utilise tapes and other adhesive methods to obtain reliable data. This is great for the early-stage testing and evaluation of surface treatment systems, but also for specific projects and on-going quality testing.

Tantec UK & Ireland’s experts carry out contact angle testing as an advanced method of measuring surface energy, just like dyne pens and test inks.

This alternative way of testing has two key benefits:

1. The result is a digital, single figure that requires little or no operator intervention. As a result, it is accurate and repeatable.

2. The total surface energy consists of two values – the polar and disperse energy of the material. The dispersed energy throughout the material is present in everything but often has little or no influence on adhesion. In contrast, the polar energy is usually key to the bonding process, therefore knowing you have the right amount can clarify your material’s performance better than inks can.

For example, a high surface energy material with no polar content will pass with inks – but still not bond. However, a low surface energy material with high polar content would fail using inks but still provide good adhesion.

These tests are routinely used to determine how a material reacts with different levels of surface treatment or to investigate levels of cleanliness. Once you know how your material works, you can assign values against performance, making it an excellent quality tool for manufacturers. This is available as part of equipment investigations, manufacturing processes and one-off projects.

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com