With over 40 years of experience producing premier surface treatment equipment, we’ve got a wealth of expertise that we pour into our technologies. This shows in our strong line up of equipment, and in our after sales support – having solved problems around the world, in a wide variety of production environments.

We’re proud to offer our customers an innovative range of products consisting of treatments suitable for multiple industries. Whatever sector you’re in, whether it’s aerospace, automotive, defence, marine or medical devices, we’ll have a range of solutions for you.

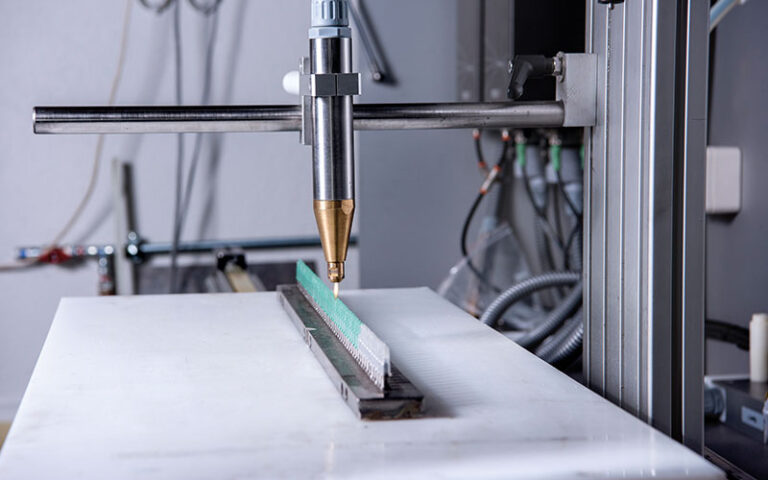

An excellent method for creating a targeted, high-performance treatment, Atmospheric Plasma utilises a powerful jet of energised compressed air directed at a component’s surface. This is a great way of increasing the adhesive properties of selective areas of a surface, making it much easier to bond, paint or glue.

Tantec UK & Ireland are expert’s in Atmospheric Plasma Surface Treatments and have built a versatile portfolio of world-class systems, capable of operating as standalone entities or as part of an automated industrial assembly line.

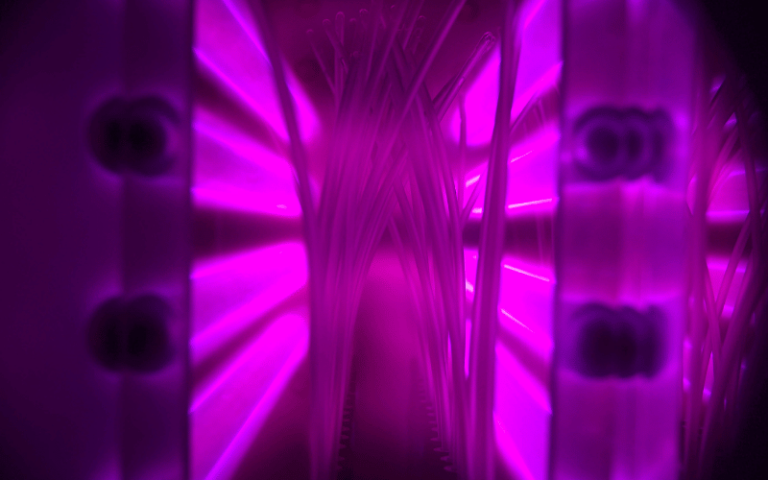

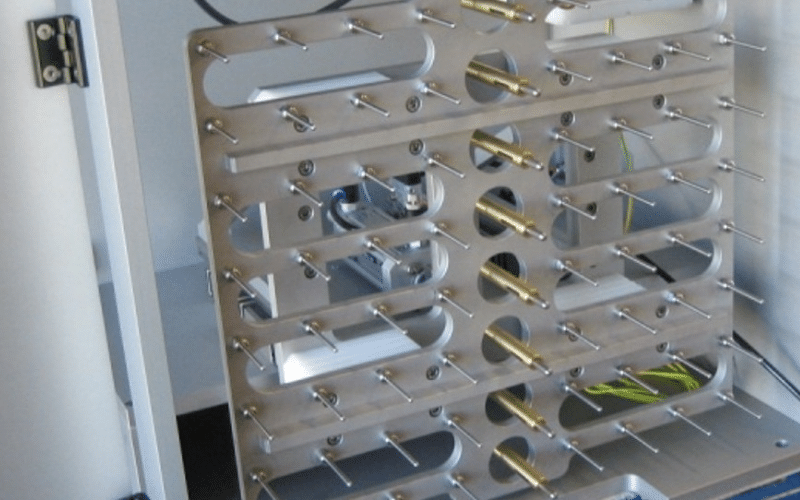

Vacuum Plasma is arguably one of Tantec UK & Ireland’s most sought-after processes; indeed it is one of our most impressive. It’s ability to treat 100% of a component’s surface is incredibly useful for large parts or those with complex geometries. High-quality cleaning, surface activation, deposition and etching treatments can all be completed ahead of the painting, gluing or coating.

If you have a wide portfolio of products or are looking to do a variety of production runs without costly changeover times, then these Plasma Surface Treatment Systems are the solutions for you.

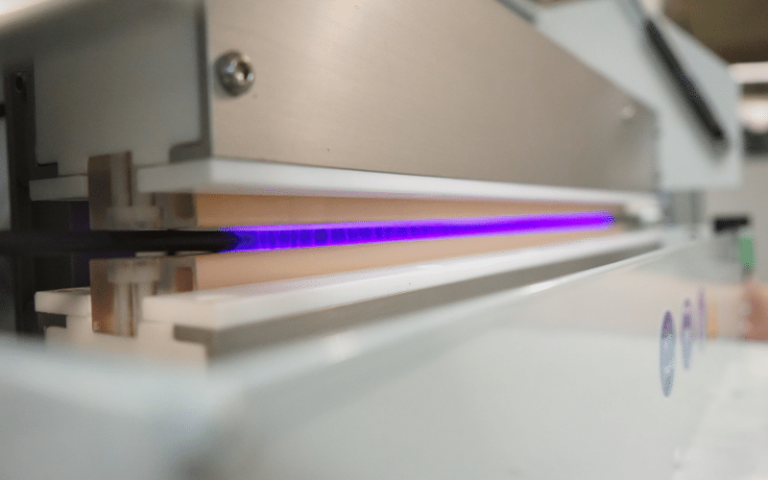

Corona Surface Treatments are designed to increase surface energy across a wide variety of metals and plastics. By adding these adhesive properties to a material, a range of printing or bonding processes can then take place.

We delivered our first Corona Treatment Systems in 1974, so you could say we’re highly experienced in this field. Since that day, we’ve developed a reputation as a trusted supplier of Corona Surface Treatment Systems to customers across a wide-range of industries including the plastic film, extrusion, automotive and medical sectors.

Tantec UK & Ireland’s innovative ozone treatment system – OzoneTEC – provides a unique way of treating cavities and areas other methods would be unable to reach. It is an ideal solution for products consisting of a sandwich construction and hollow cavity such as rotationally moulded parts where foam injection is required. These could be anything from surfboards, coolers and ice boxes to jacket pipes and small boats – certainly a varied array of applications.

Leak detection is the process of using a non-destructive electrical current to detect any holes, defects or abnormalities in non-conductive single layer materials. Tantec UK & Ireland’s premier leak detection system – LeakTEC – is a fantastic tool to provide the user with 100% quality when inspecting products. Thanks to our innovative system, dozens of parts can be checked every second, giving you a rapid, reliable operation.

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com