As companies come under increasing pressure to mitigate the damage their actions have on the environment, the need for more efficient, effective technologies is getting bigger and bigger. Manufacturers in the aerospace, automotive and medical devices markets – as well as other sectors – are turning to greener technologies that can still meet the stringent performance standards they expect. Combined with the fact that many chemicals are now no longer available due to their place on the REACH list, then the need for alternative solutions is greater than ever. For example, the infamously strong and effective cleaning chemical – chemical trichloroethylene (TRIC) – has been phased out over the last couple of decades.

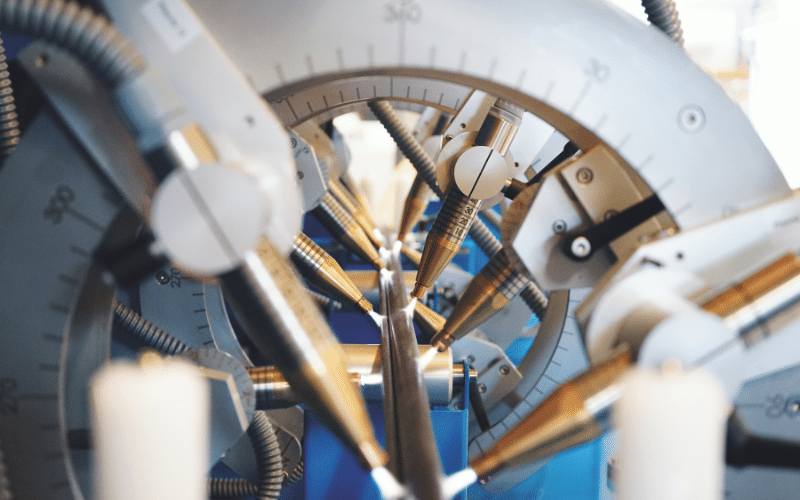

As a result, Tantec UK’s diverse portfolio of corona and plasma surface treatment systems have helped many customers in high-technology markets vastly improve their environmental credentials. At the same time, we’ve also driven the performance of their products to exciting new levels.

Our innovative, next-generation corona and plasma treatment systems eliminate the need for hazardous chemicals found in solvents and primers. We’ve developed environmentally-friendly processes that effectively clean components without the dispersal of toxic chemicals into the atmosphere. This enables us to not only safely remove any contaminants as the parts are prepared for processing, but simultaneously increase the component’s surface energy. We can achieve more reliable, adhesive bonding and painting performance without the use of volatile organic compounds (VOC). It’s a win-win scenario for our customers, giving them a better performing, more environmentally friendly product.

Reduce your energy consumption – and the cost of your electricity bills – with Tantec UK’s energy-efficient corona and plasma surface treatment systems. Unlike traditional, energy-intensive manufacturing processes, our state-of-the-art, cost-effective systems offer substantial benefits – both financially and environmentally. For example, the drying stage of a conventional wet chemistry process drains substantially more energy than the amount used by our plasma treatment systems, which often run at under 1kw. All of our systems offer clean, highly-repeatable processes that are much better for both the environment and your employees.

Your employees want – and deserve – a safe, professional working environment where they can perform their role effectively. Our cutting-edge corona and surface treatment systems remove the need for hazardous chemicals present in solvents and primers, preventing their release into the local atmosphere. This eliminates the risk to employees from inhaling or coming in to physical contact with these chemicals and experiencing potentially harmful consequences.

Instead, our clean, consistent plasma and corona surface treatment systems ensure operator actions remain limited to loading, unloading and pressing “go”, or even less when coupled with an automation cell. Since they operate solely using electricity and air, they don’t need to worry about harmful substances.

A great example is our work with a number of OEM, tier one and tier two automotive manufacturers. These organisations, especially when it comes to interior applications, use a range of materials that must be structurally sound before going out on the road. A large number of interior components, whether it’s plastic trims or the dashboard, consist of multiple materials such as bonded foams and leather-effect coatings. These all have to be bonded tightly, performing their roles within the vehicle. Therefore it’s vital that their surfaces are treated and prepared to enable the best adhesive performance possible.

Our clean, environmentally-friendly plasma and corona processing systems have helped customers across multiple industries lower their production costs. Not only are they energy efficient and reduce costs, but the simplification of their operations has produced better, more consistent and higher performing products. Tantec UK’s technologies also substantially reduce component rejection rates and the associated energy costs required to re-work them back through the manufacturing process to an acceptable standard.

Are you looking for a reliable partner able to offer environmentally-friendly corona and plasma surface treatment solutions? Do you need to improve the conditions of your manufacturing environment, reduce costs and want to drive product performance in the process? Contact one of Tantec UK’s friendly experts today to discuss how our cutting-edge corona and plasma surface treatment systems can help!

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com