They trust our unrivalled knowledge and expertise when it comes to treating their products and helping them to maximise performance.

Our proficiency in surface treatments is usually sought during the manufacturing process when parts require pre-treatment prior to other operations or at the end where we can undertake further processing, assembly and manufacture into the finished product. With our comprehensive range of services including gluing, coating and printing – Tantec UK and Ireland is the ideal partner for integrated sub-contract manufacturing services.

Our specialist sub-contracting arm, Ebble Manufacturing, is ideal for small-to-medium throughput projects where capital equipment or personnel training isn’t suitable for the job. With over £100,000 worth of state-of-the-art machinery, it’s an excellent resource for short projects, low throughput and as back-up for current manufacturing teams.

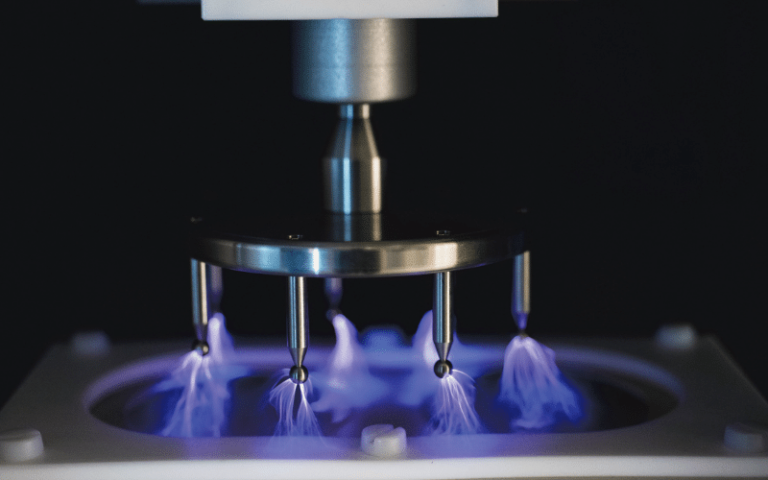

Furthermore, if you’re considering purchasing Tantec UK & Ireland’s world-leading plasma and corona systems, it’s a fantastic opportunity to use us before committing to an order. We can also help with production ramp-up head of delivery for longer lead-time machines.

As a company with nearly 50 years of experience specialising in plasma and corona surface treatments, our customers know they’re partnering with industry experts. They often approach us because they’re fulfilling one of their own customer’s demands; albeit not sufficient enough to invest in capital equipment for one client only. Alternatively, we’re also a fantastic solution to be used as a manufacturing overhead without overwhelming any current systems.

Our experts often consult with customers who either haven’t used – or even heard – of our technologies before. On many occasions, they were unaware of the investment required before speaking with us. By using our sub-contract manufacturing services, customers can ease themselves into the world of plasma and corona surface treatment systems without spending tens of thousands buying, installing and operating their own equipment.

They were in the process of developing a new car for next season, therefore they had considered buying their own vacuum plasma system to process parts. However, they only had a few parts and hadn’t received sign off in time to purchase the new machine.

As the materials were metal and reasonably large, we treated them using our VacuTEC system. We rapidly turned them around to such an extent that the customer hand-delivered them and waited whilst they were treated before taking them back on-site for processing.

As a result, Tantec UK & Ireland gave the client the data and results required, enabling them to build a fantastic car for the following season.

As a company with nearly 50 years of experience specialising in plasma and corona surface treatments, our customers know they’re partnering with industry experts. They often approach us because they’re fulfilling one of their own customer’s demands; albeit not sufficient enough to invest in capital equipment for one client only. Alternatively, we’re also a fantastic solution to be used as a manufacturing overhead without overwhelming any current systems.

Our experts often consult with customers who either haven’t used – or even heard – of our technologies before. On many occasions, they were unaware of the investment required before speaking with us. By using our sub-contract manufacturing services, customers can ease themselves into the world of plasma and corona surface treatment systems without spending tens of thousands buying, installing and operating their own equipment.

A motorsport customer approached the team at Tantec UK & Ireland regarding sub-contract services. They were in the process of developing a new car for next season, therefore they had considered buying their own vacuum plasma system to process parts. However, they only had a few parts and hadn’t received sign off in time to purchase the new machine.

As the materials were metal and reasonably large, we treated them using our VacuTEC system. We rapidly turned them around to such an extent that the customer hand-delivered them and waited whilst they were treated before taking them back on-site for processing. As a result, Tantec UK & Ireland gave the client the data and results required, enabling them to build a fantastic car for the following season.

40A Crossgate Road

Park Farm Industrial Estate

Redditch

B98 7SN

Tel: 01527 304 004

Email: info@tantec-uk.com